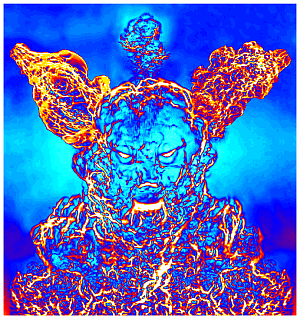

“High speed schlieren photography of pre-chamber generated turbulent jet ignition of lean CH4/air – potential solution to ultra lean combustion. Devil’s face is made of wrinkled turbulent flames. Horns are composed of two flame-jets from pre-chamber combustion. The hot puff on top of devil’s head represents initiation of ignition in main combustion chamber. This image contains all three phases of prechamber generated jet ignition process, namely, the pre-chamber flame-jet, main chamber ignition point and flame propagation.”

Sayan Biswas and Li Qiao (Purdue University)

“Flamelets in an iron particle suspension passing through quenching channels. Agglomerates burn discretely in the afterglow of the flame.”

Michael Soo, Jan Palecka, Phil Julien, Sam Whiteley, James Vickery, Sam Goroshin, David Frost and Jeff Bergthorson (McGill University)

“The pictures were taken for fuel flexibility experiments carried out at the University of California Irvine Combustion Laboratory (UCICL). The pictures show the structure of premixed flames with multiple fuel compositions and air to fuel ratios (only on the fuel lean regime). The fuel compositions used include fuel blends of hydrogen, natural gas and biogas.

The burner presented in the picture uses a porous material to stabilize the reactions. The porous ceramic burner presented in the pictures is the Duratherm™ by ALZETA Corp.”

Andres F. Colorado (University of California Irvine)

“Each eye is actually an image of a burning droplet with its surrounding soot and flame, suspending from a carbon fiber in normal gravity. The fuel used for this experiment was diesel doped with 3% (by weight) of a very heavy polymer, Polybutadiene, to investigate the effect of polymer additives on combustion characteristics. Due to presence of polymer, there is a period during which the droplet undergoes strong bubbling and swelling and takes many irregular shapes. Through sputtering, plumes of gas leave droplet surface and change flame standing and soot shell distribution. The image has been just colored and all the shadows around the eye are natural and represent the location of a very sooty flame around the droplet. For this experiment images were taken at 500 frames per second and the mean droplet diameter in the instant shown is about 0.55 mm.”

Mohsen Ghamari and Albert Ratner (University of Iowa)

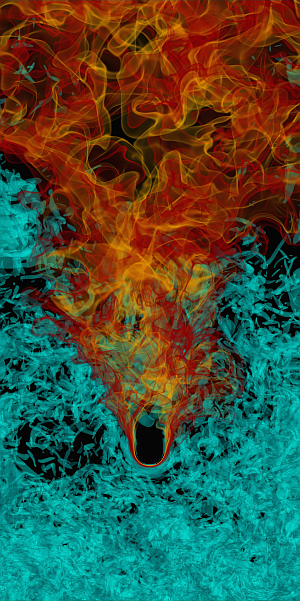

“Turbulence-flame interaction is a key to turbulent combustion modeling. Except for statistically one-dimensional planar turbulent flames, mean flow features such as shear layers also influence the interaction. The V-flame is one of flame configurations that emphasize this additional complexity due to flame geometry. A turbulent hydrogen-air V-flame has been simulated using the direct numerical simulation methodology. The image shows volume rendered vortices (cyan) and temperature field (red-yellow). The interaction characteristics change with the streamwise distance (vertical distance from the bottom). Near the flame holder, local flames interact with quite a few vortices parts of which are generated by the mean shear or wake behind the flame holder. The vortices quickly decay to have small effect on reaction zones in the downstream.”

Yuki Minamoto (Sandia National Laboratories) and Mamoru Tanahashi (Tokyo Institute of Technology)

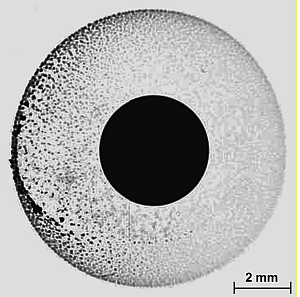

“Tiny soot particles are visible around a free-floating and stationary n-decane droplet in this image at one instant of the droplet burning history. External convective effects are absent. The resulting thermal symmetry leads to soot aggregates forming a spherical porous cloud (the flame, not visible, is about ten times the droplet diameter). This symmetric configuration of trapped soot aggregates belies the complexity of the processes that bring about its existence.”

Yuhao Xu (Cornell), Yu-Cheng Liu (U. Michigan-Flint), Michael Hicks (NASA) and Thomas Avedisian (Cornell)